Introduction to Oil – water Separation :

Oil water separation is common in industry and various methods adapted for the same are :

• Adhesion skimmers such as disc skimmers, belt skimmers, drum type skimmers, etc.

• Gravity separators

• Membrane filters & centrifuges

• Oil Coalescer systems

In all these methods oil coalescer is found to be more valuable for oil control for precious process fluids such as machine coolant, aqueous cleaning solution, cooling water etc.

Oil skimmers are useful in case of removal of floating oil only. Gravity separators primarily collect the oil; they build an oil layer inside the separator, resulting in long contact time. Oil coalescer uses gravity separation but adds the “three step separation” mechanism. The result is very short contact time.

When the oil is dispersed in the process fluid in the form of small globules then the best way for oil water separation is use of coalescer system.

Operating principle of Coalescers :

Liquid-Liquid Coalescers are used to accelerate the merging of many droplets to form a lesser number of droplets, but with a greater diameter. This increases the buoyant forces as per the Stokes Law equation. Settling of the larger droplets downstream of the coalescer element then requires considerably less residence time. Coalescers exhibit a three-step method of operation.

• Collection of Individual Droplets

• Combining of Several Small Droplets into Larger Ones

The clear aqueous fluid is distinctly recognizable.

• Oil is accumulated and concentrated in the coalescer area.

A brownish layer is formed at the surface, an oil film is built.

• Oil builds up a thick layer in front of the oil weir.

Oil is concentrated before separation.

• Oil is separated over the oil weir.

Only oil pass over the weir

System Description :

The oil coalescing system is a skid-mounting unit consisting of :

• Suction float assembly for contaminated liquid collection from tank

• Air operated double diaphragm pump

• Oil coalescer tank with oleophilic coalescing media, tank drain valve and outlets for separated oil & clean fluid

• Mounting skid / Base frame for coalescer tank & pump

The air operated diaphragm pump collects the contaminated liquid from the source tank through the float assemblies. Part of the flow is diverted back to tank so as to maintain laminar flow of contaminated liquid in the coalescer tank.

Rise / Fall of the Enlarged Droplets by Gravity :

Submicron droplets flow around target. Droplets strike target and adhere. Several captured droplets coalesce, forming larger drops, which trickle down and rise or fall, becoming separated.

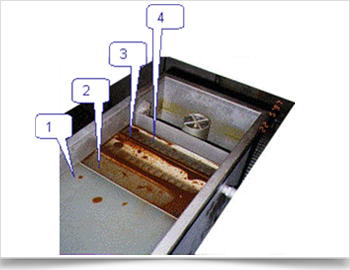

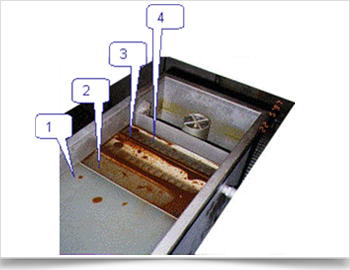

Typical arrangement of oil coalescer tank is as shown :

Oil traces coming to the surface.

When the liquid passes through the coalescer media, oil droplets coalesce and get separated. The clean liquid is delivered back to source tank. The oil will be collected in the waste oil drum.

Constructional Details :

Coalescing tank, support structure is of MS duly painted with Epoxy paint RAL 7047 externally and with Industrial white oil paint for tank internal surfaces. Floats are of HDPE. The tank is provided with sloping bottom for proper sludge settling arrangement.

|