|

Home | Contact Us |

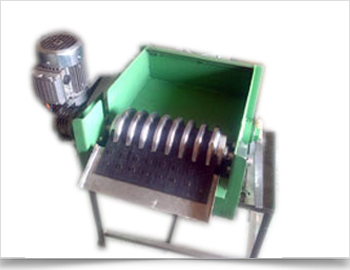

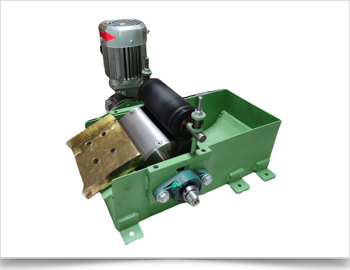

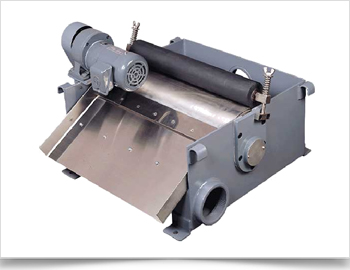

Centralised Coolant Filtration Systems | Centralised Oil Filtration Systems | Coolant Filtration Systems | Oil Filtration Systems | Precoat Filters | Vacuum Band Filters | Coolant Sump Cleaners | Chip Conveyors | Centralised Chip Conveyors | Chip Handling System With Chip Wringer | Chip Wringers | Flat Bed Pressure Filters | Paper Band Filters | Magnetic Separators | Roll Coolant Filtration Systems | Mobile Filtration Systems | Oil Skimmers | Oil Coalescers | Sludge Drying Units | Sludge Compacting Machines | Spares For Filtration Systems | Spares For Chip Conveyor | Cartridge Filters | Bag Filters | Self-Cleaning Filtration System | Oil Recovery Press (ORP) | Home | About Us | Products | Contact Us | Enquiry |

Designed by : MID Hosted by : GID Promoted by : PBD